How to Secure Injection Molding Services with Chinese Suppliers

So, the big meeting just wrapped up. your new project has the green light, time is pressing, and the budget is, let’s say, constrained.. Then a voice—perhaps your manager or the CFO—drops the line that gives every project manager a shock: “We should look at sourcing this from China.”

Naturally, you agree. It makes sense on paper. The potential savings can be massive. But your mind is already racing. You know the rumors, don’t you? The nightmare of defective parts, opaque communication, and delayed, off-spec shipments. It feels like walking a thin line between big savings and total project failure.

Here’s the thing, though. Procuring plastic mold needn’t be a roll of the dice. It’s no different from any structured project. And as with any project, success depends on your methodology. It’s not just about the lowest bid but selecting the best partner and overseeing every step. Ignore the nightmare anecdotes. Let’s go through a step-by-step guide to succeed.

Step One: Do Your Homework

Before you even whisper the word “supplier” or open a browser tab to Alibaba, you need to get your own house in order. Honestly, more than half of all overseas manufacturing problems start right here, with a weak or incomplete information package. You cannot expect overseas partners to interpret your unspoken requirements. Sending a vague request is like asking a builder to quote you for “a house.” The replies will range from absurdly low to exorbitant, none of which help.

Aim to craft an RFQ package so precise and comprehensive it leaves no room for error. This package is your project’s foundation.

So, what goes in it?

Start with your 3D design files. These are non-negotiable. Use standard formats such as STEP or IGS to ensure compatibility. This is the master blueprint for your part’s geometry.

But 3D isn’t enough. Add comprehensive 2D plans. This is where you call out the stuff that a 3D model can’t communicate. Examples include tolerances (e.g., ‘25.00±0.05 mm’), material grade, surface finish requirements, and functional callouts. If a specific surface needs to be perfectly smooth for a seal, or a particular hole diameter is vital for an assembly, your 2D drawing needs to shout it from the rooftops.

Next up, material. Don’t just say “Plastic.” Even “ABS” alone is too vague. Be explicit. If you need SABIC Cycolac MG38 in black, say exactly that. Why? Because resin grades number in the thousands. Defining the exact material guarantees the performance and appearance you designed with what is plastic mold.

They can offer alternatives, but you must provide the initial spec.

Finally, include the business details. What is your Estimated Annual Usage (EAU)? They need clarity: is it 1,000 total shots or a million units per annum? The tool design, the number of cavities, and the price per part all hinge on this number.

The Great Supplier Hunt

Okay, your RFQ package is a work of art. who will you target? The internet has made the world smaller, but it’s also made it a lot noisier. It’s easy to find a supplier; it’s hard to find a good one.

Begin on popular marketplaces such as Alibaba or Made-in-China. These are great for casting a wide net and getting a feel for the landscape. Use them to build a shortlist, not the final list. Narrow your pool to about a dozen promising firms.

However, don’t end your search there. Think about engaging a sourcing agent. Yes, they take a cut. But a good one has a vetted network of factories they trust. They handle local liaison and oversight. As a newcomer, this offers priceless security. Think of it as insurance for your project timeline.

Also consider trade fairs. If you can attend, shows such as Chinaplas transform sourcing. In-person meetings trump emails. Hold samples, talk shop, and gauge professionalism firsthand. Plus, ask peers for referrals. Ask other project managers in your network. A solid referral can be more valuable than any ad.

Sorting the Contenders from the Pretenders

With your RFQ dispatched to dozens of firms, the quotes will start trickling in. Some prices will undercut logic, others will shock you. Now, sift through and shortlist 2–3 reliable candidates.

How to proceed? It involves both metrics and gut feel.

Step one: audit communication. Do they respond quickly and clearly? Do they communicate effectively in English? The true litmus: are they raising smart queries? Top vendors will critique and inquire. “Have you considered adding a draft angle here to improve ejection?” or “We see your tolerance requirement here; our CMM can verify that, but it will add to the inspection time. Is that acceptable?” This is a massive green flag. It proves their expertise and involvement. A “Sure, no issues” vendor often means trouble.

Next, dig into their technical capabilities. Request their machine list. More importantly, ask for case studies of parts they’ve made that are similar to yours in size, complexity, or material. Don’t pick a micro-molding shop for large components.

Then comes the audit. Skipping this is a mistake. As you vet staff, you must vet suppliers. Either visit in person or engage a local audit service. They perform a one-day factory inspection. They authenticate the firm, review ISO credentials, evaluate machines, and survey operations. That small investment can save you thousands.

From Digital File to Physical Part

Once you’ve chosen your supplier. you’ll agree on terms, typically 50% upfront for tooling and 50% upon first-sample approval. Then comes the real action.

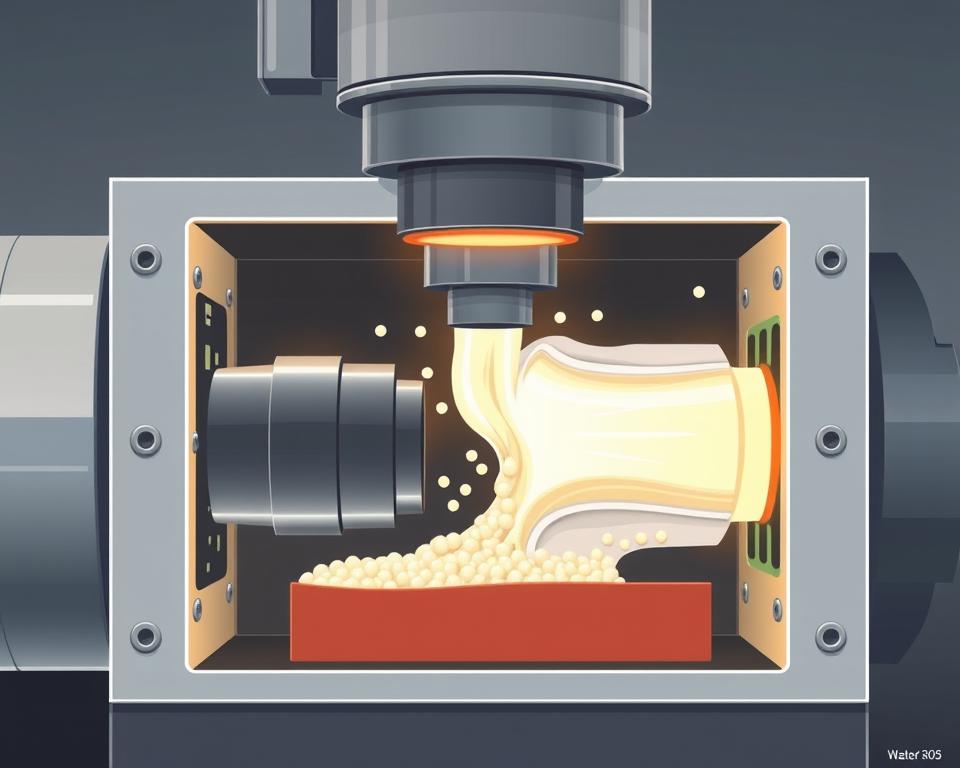

The first thing you should get back after sending your payment is a DFM report. Design for Manufacturability (DFM) is essential. It’s the engineering critique for moldability. The report calls out sink-risk zones, stress-causing corners, and draft angle gaps. A detailed DFM shows expertise. It’s a two-way partnership. You iterate with their team to optimize the mold.

With DFM sign-off, toolmaking begins. In a few weeks, you’ll see “T1 samples are on the way.” These are your initial mold shots. It’s your first real test.

Be prepared: T1 samples are almost never perfect. That’s standard process. Look for small flaws, slight size errors, or surface marks. You critique, they refine, and T2 plastic mold in China parts arrive. You may repeat this cycle a few times. Plan for this loop in your schedule.

At last, you get the perfect shot. It meets every dimension, the finish is flawless, and it functions exactly as intended. This is your golden sample. You sign off, and it serves as the master quality reference.

Completing the Sourcing Journey

Receiving the golden sample seems like victory, but you’re not done. Next up: mass manufacturing. How can you keep part #10,000 matching your golden sample?

You need a clear Quality Control plan. This often involves a pre-shipment inspection. Again, you can hire a third-party service. For a few hundred dollars, they will go to the factory, randomly pull a statistically significant number of parts from your finished production run, and inspect them against your 2D drawing and the golden sample. You receive a full report with images and measurements. Only after you approve this report do you authorize the shipment and send the final payment. This step saves you from a container of rejects.

Lastly, plan logistics. Know your shipping terms. Does FOB apply, passing risk at the ship’s rail? Or EXW, shifting all transport to you? These choices hugely affect landed cost.

China sourcing is a long-haul effort. It relies on partnership-building. Treat them like a partner, not just a line item on a spreadsheet. Open dialogue, trust, and rigorous procedure deliver results. It’s a challenging project, no doubt. But with this framework, it’s one you can absolutely nail, delivering the cost savings everyone wants without sacrificing your sanity—or the quality of your product. You’ve got this.